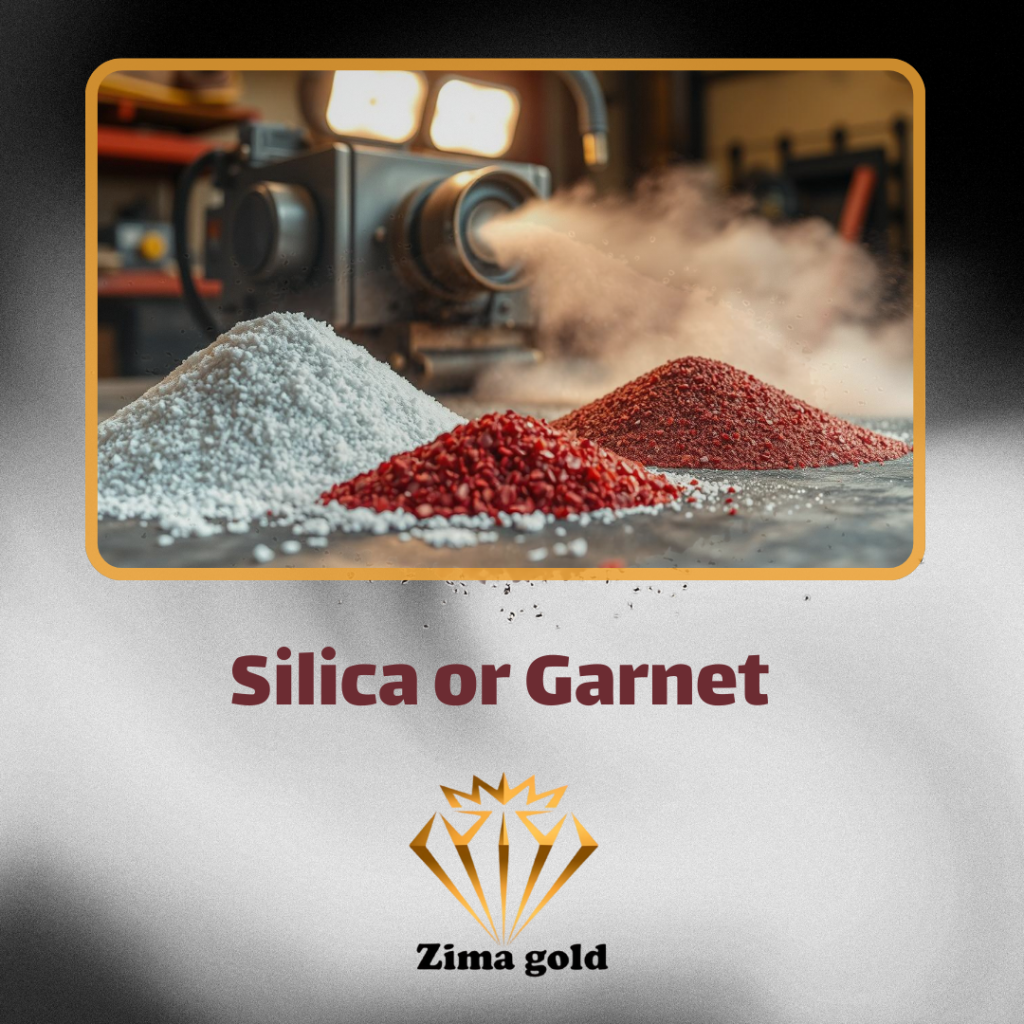

Silica and garnet are two important materials in the sandblasting industry. They serve as abrasive particles for cleaning and surface preparation. In this article, we will explore the differences between silica and garnet in sandblasting and explain the advantages and disadvantages of each.

Silica and garnet are widely used in surface preparation and cleaning operations. Understanding the specific features of each can aid in selecting the most suitable material for sandblasting.

Key Differences Between Silica and Garnet in Sandblasting

- Silica and garnet are commonly used materials in the sandblasting industry.

- Each of these materials has unique advantages and disadvantages in sandblasting applications.

- Awareness of the differences between these two materials helps in making the best choice for sandblasting projects.

- Performance, cost, and lifespan of each material in the sandblasting process vary.

- Comparing the properties of silica and garnet assists in choosing the most suitable material for different purposes.

Differences Between Silica and Garnet in Sandblasting

In sandblasting, selecting the right mineral materials is crucial. Silica and garnet are two frequently used materials, each with specific characteristics that should be taken into account.

Characteristics Comparison

| Feature | Silica | Garnet |

|---|---|---|

| Hardness | High | Very High |

| Abrasion Resistance | High | Very High |

| Cost | Affordable | Higher |

| Lifespan | Medium | Longer |

| Efficiency in Paint Removal | Medium | Higher |

Both materials have unique properties that need to be considered when selecting a sandblasting material. Comparing silica and garnet and understanding their performance in sandblasting helps in making an informed choice.

Advantages of Using Silica in Sandblasting

Using silica in sandblasting offers numerous advantages, making it an efficient and economical option. Two key benefits are its superior performance in high-pressure processes and its lower costs compared to other options like garnet.

Better Performance in High-Pressure Processes

Due to its hardness and high abrasiveness, silica can create smoother and more uniform surfaces. This characteristic enables sandblasting with silica to provide better results in various fields, including metal surface preparation and paint removal.

Lower Costs

In addition to better performance, the cost of sourcing and using silica in sandblasting is lower. This economic advantage makes silica a more suitable option for many industries and applications.

Statement

“Silica, due to its higher hardness and abrasiveness compared to garnet, can create smoother and more uniform surfaces in high-pressure processes.”

Advantages of Using Garnet in Sandblasting

Garnet also has numerous advantages in sandblasting. This hard and dense material possesses particular characteristics that enhance its effectiveness.

Longer Lifespan

Garnet has a much longer lifespan in sandblasting compared to silica. It can withstand thousands of abrasions while maintaining its effectiveness.

Higher Efficiency in Paint Removal

Garnet performs better in paint removal. This allows for better results in sandblasting operations.

Overall, garnet’s many advantages make it an ideal choice for various applications in sandblasting.

Choosing Between Silica and Garnet: Influencing Factors

When deciding between silica and garnet for sandblasting, several factors are important. This choice depends on the industry’s needs and the specific project.

Influencing Factors

- Type of Surface Being Processed: Different surfaces may require specific characteristics from the abrasive materials.

- Environmental Conditions: Weather and environmental conditions can influence the performance of the abrasive materials.

- Budget: The costs associated with abrasive materials and the sandblasting process must be considered.

- Environmental Considerations: The impact of abrasive materials on the environment should be assessed.

By considering these factors, professionals can make the best choice between silica and garnet in sandblasting.

| Factor | Considerations |

|---|---|

| Type of Surface Processed | Smooth or rough surfaces, suitability of abrasives |

| Environmental Conditions | Temperature, humidity, pollutants affecting performance |

| Budget | Costs of abrasive materials and sandblasting process |

| Environmental Considerations | Impact of abrasives on the environment and waste management needs |

Safety and Environmental Considerations

Using silica and garnet in sandblasting can pose health risks. Inhalation of silica can lead to respiratory diseases, impacting worker health.

Effects of Silica on Health

To minimize the risk of silica inhalation, safety equipment should be used. Additionally, the work environment must be well-ventilated, and regular medical check-ups for workers are essential.

Waste Management of Garnet

The disposal of garnet waste must be carefully managed. Used garnet should be disposed of correctly to prevent environmental pollution and help preserve the ecosystem.

FAQ

What is the difference between silica and garnet in sandblasting?

Silica and garnet are both mineral materials used in sandblasting. Each has specific features that are important for choosing and utilizing them effectively.

What are the advantages of using silica in sandblasting?

Silica performs well in sandblasting and is less expensive. Its hardness and abrasive nature create smoother surfaces, and it’s more affordable to acquire and use.

What are the advantages of using garnet in sandblasting?

Garnet has a longer lifespan and performs better in paint removal. Due to its higher hardness and density, it provides improved results in surface preparation.

What factors influence the choice between silica and garnet for sandblasting?

The choice between silica and garnet depends on various factors, including the type of surface, environmental conditions, budget, and environmental considerations. Professionals must weigh these needs to make the best choice.

What safety and environmental considerations should be taken when using silica and garnet in sandblasting?

Using silica and garnet can have adverse effects on health and the environment. Inhalation of silica can lead to respiratory diseases, and proper waste management of garnet is crucial to prevent environmental pollution. Adhering to safety and environmental guidelines is essential.