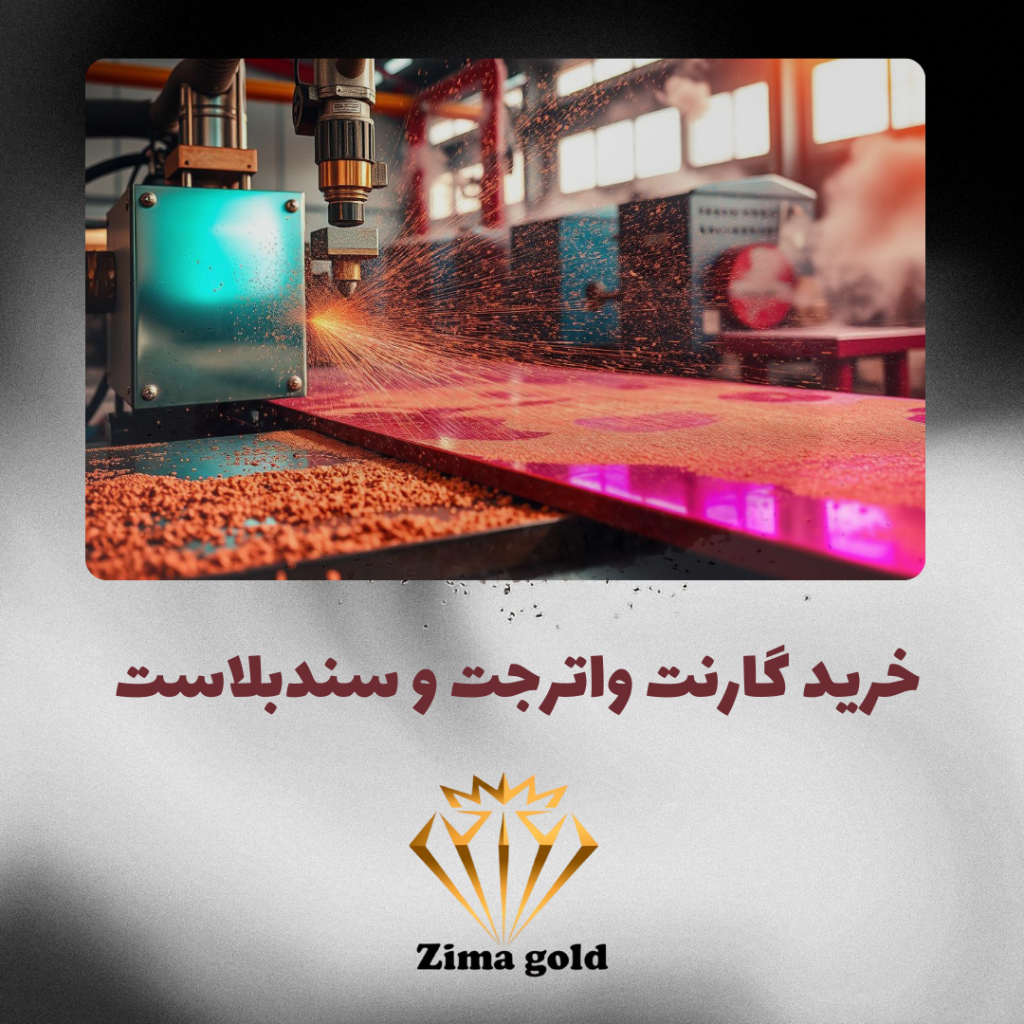

Buying Garnet for Waterjet Cutting and Sandblasting

Buying Garnet for Waterjet and Sandblasting .Garnet is widely used in waterjet cutting and sandblasting processes due to its unique properties. It serves as an effective tool for cleaning and cutting various materials. Nowadays, precise cleaning and cutting methods are vital, playing a crucial role in completing industrial projects. The use of garnet in waterjet and sandblasting processes proves to be highly efficient.

Overview of Garnet Options and Their Advantages

This article will examine the different types of garnet and their benefits. We will also discuss how to choose and procure the suitable garnet for these processes.

Types of Garnet Suitable for Waterjet Cutting and Sandblasting

Garnets used in waterjet and sandblasting can be categorized as follows:

- Almandine Garnet: The hardest and most resilient type, widely used in the waterjet industry.

- Pyrope Garnet: Known for its high hardness and resistance, suitable for sandblasting applications.

- Grossular Garnet: A clearer type, appropriate for specialized waterjet and sandblasting applications.

- Spessartine Garnet: A type with high hardness and cutting power, suitable for heavy-duty tasks.

Advantages of Using Garnet in Waterjet and Sandblasting Processes

Utilizing garnet in waterjet and sandblasting offers significant advantages:

- High hardness and wear resistance lead to desirable operational outcomes.

- Various sizes available, allowing selection based on application type and final surface requirements.

- Lower costs compared to other similar abrasive materials.

- Possibility of recycling and reusing used garnets.

Choosing the right garnet can yield optimal results in waterjet cutting and sandblasting processes, enhancing the quality and efficiency of these operations.

Applications of Waterjet and Sandblasting with Garnet

Garnet is a powerful tool in waterjet cutting and sandblasting, applicable in various industries for surface cleaning, cutting, and engraving.

Surface Cleaning

Surface cleaning is one of the primary applications of waterjet and sandblasting using garnet. These processes can effectively clean various surfaces such as metals, stone, concrete, etc. Garnet ensures thorough cleaning in these operations.

Cutting and Engraving Materials

Waterjet and sandblasting with garnet are used for cutting and engraving different materials. These processes can precisely create intricate shapes and designs on various surfaces, making them particularly useful in artistic and decorative industries.

How to Choose the Right Garnet for Waterjet and Sandblasting

When purchasing garnet for waterjet and sandblasting, several important criteria should be considered, including:

- Size: Different garnet sizes are suitable for various applications. Smaller sizes are ideal for more precise cleaning, while larger sizes are better for cutting and engraving.

- Hardness: Harder garnets are better for cutting and engraving harder materials, while softer garnets are more suitable for cleaning delicate surfaces.

- Purity: Higher purity garnets have better performance by producing less contamination and improving result quality.

- Price: While price is essential, it should not be the sole consideration, as sometimes more expensive garnets offer better performance.

Taking these factors into account can lead you to the appropriate garnet for your needs, ensuring optimal performance and quality results.

Sources for Quality Garnet Supply for Waterjet and Sandblasting

Choosing the right garnet is crucial for enhancing the efficiency and quality of these processes. Below are some reputable companies known for supplying garnet:

- Zima Gold Garnet Company

- Zanobar Iranians Company

With quality garnet from these suppliers, your waterjet and sandblasting processes will achieve the best results.

Costs of Purchasing Garnet for Waterjet and Sandblasting

The quality of garnet significantly affects the cost of waterjet and sandblasting processes. Thus, it’s vital to analyze these costs.

Several factors influence garnet pricing, including:

- Quality and size of garnet grains

- Hardness and resistance level

- Market fluctuations and changes in raw material pricing

- Transportation and sourcing costs

Higher-quality garnet with finer grains typically comes at a higher price. Shipping and supply costs also impact the overall price.

To reduce garnet costs, consider the following strategies:

- Bulk purchases and advance payments for discounts

- Using recycled and cleaned garnets

- Comparing prices and choosing suitable suppliers

- Being mindful of your budget and planning accordingly

Ultimately, the cost of purchasing garnet is just one part of the overall expenses in waterjet and sandblasting processes. Energy costs, labor, and equipment also play significant roles.

Safety Tips When Working with Garnet in Waterjet and Sandblasting

Working with garnet in waterjet and sandblasting poses health and safety risks. Therefore, adhering to safety guidelines is imperative. To protect yourself, use personal protective equipment such as masks, goggles, and protective clothing.

Controlling the concentration of garnet particles in the workplace is also crucial. If levels are high, employing ventilation and air purification systems is advised to prevent air pollution and respiratory issues.

Training staff on the proper use of equipment and safety principles is essential for fostering a safety culture in the workplace and preventing unfortunate incidents.

FAQ

Why is Garnet the Best Choice for Waterjet and Sandblasting Processes?

Due to its high hardness and wear resistance, garnet is an ideal choice. Its affordability also makes it an excellent option.

What Types of Garnet Are Suitable for Purchase for Waterjet and Sandblasting?

Almandine, Australian, and Chinese garnets are among the best and are suitable for waterjet and sandblasting.

What Advantages Are There in Using Garnet for Waterjet and Sandblasting?

Advantages include high cutting power and increased efficiency, resulting in reduced processing time and costs.

How Can One Select the Right Garnet for Waterjet and Sandblasting?

Choosing the right garnet involves considering size, hardness, purity, and price, which helps ensure optimal performance.

Which Reputable Companies Supply Quality Garnet for Waterjet and Sandblasting?

Zima Gold Garnet and Zanobar Iranians are among the trusted suppliers for quality garnet.