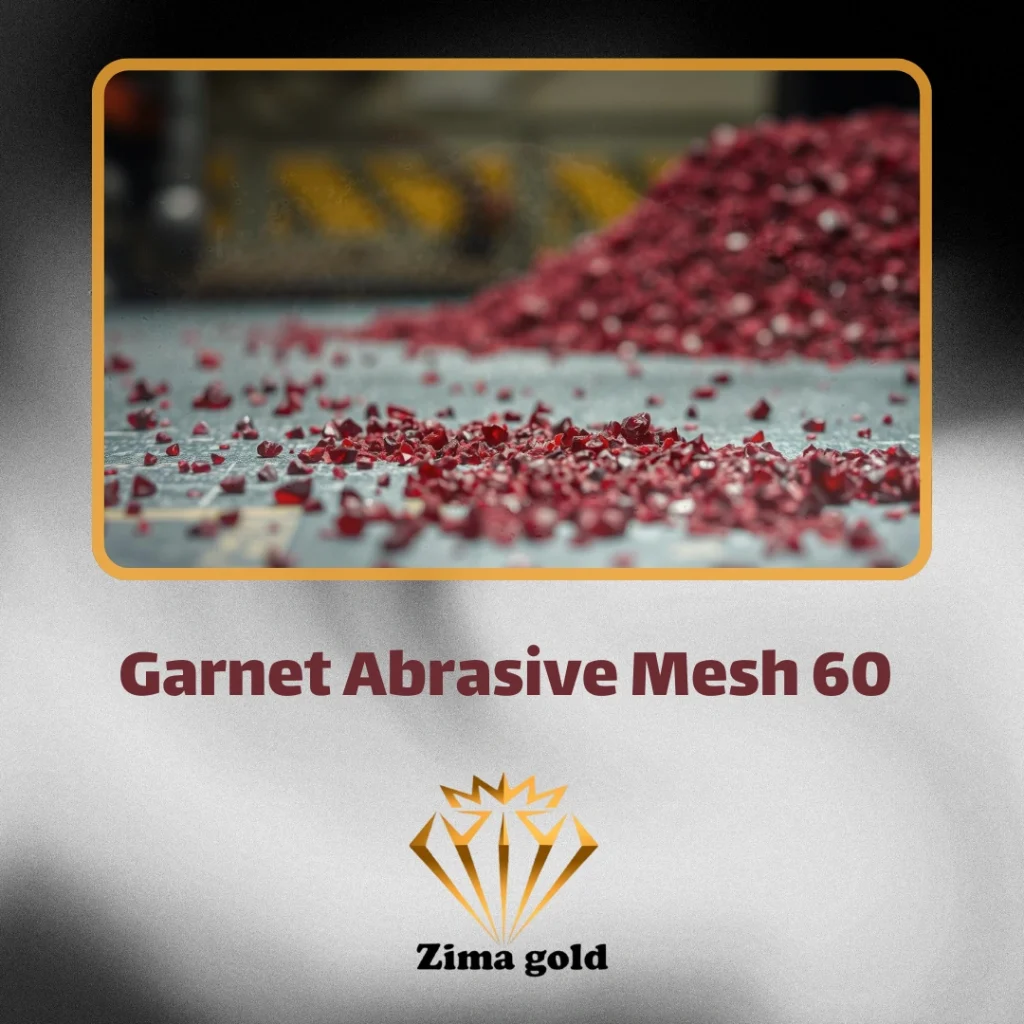

Garnet Abrasive Mesh 60

Garnet mesh 60 is a widely used abrasive in the sandblasting industry. This high-performance abrasive is recognized for its durability and environmental compatibility. Many users utilize it due to its unique characteristics.

In this article, we will introduce garnet and its important features. Additionally, we will explore its applications in various industries.

Key Points

- Garnet is one of the most commonly used mineral abrasives in the sandblasting industry.

- This abrasive has high performance, desirable durability, and environmental compatibility.

- Garnet mesh 60 is used in various industries such as automotive, water treatment, and construction.

- The use of garnet mesh 60 is highly appreciated due to its cost-effectiveness and high efficiency in sandblasting.

- Proper maintenance and storage of garnet mesh 60 significantly affect its performance and longevity.

Introduction to Garnet and Its Unique Features

Garnet is one of the gemstones that has applications in various industries. Its chemical composition includes aluminum silicates, calcium, iron, magnesium, and manganese. This unique composition is essential.

Chemical Structure of Garnet

The high hardness of garnet, particularly almandine and pyrope, makes it significant. The chemical formula of garnet is represented as X3Y2(SiO4)3. In this formula, X can be iron, calcium, manganese, or magnesium, while Y can be aluminum, chromium, or iron.

Physical Properties of Garnet

The hardness of garnet, measured on the Mohs scale, ranges from 6.5 to 7.5. This hardness makes it a strong abrasive material. Additionally, the density of garnet ranges from 3.5 to 4.3 grams per cubic centimeter.

Types of Garnet in Industry

In the industry, various types of garnet such as almandine, pyrope, spessartine, and grossular are utilized. Each type has unique characteristics that make it suitable for specific applications.

| Type of Garnet | Chemical Composition | Features | Applications |

|---|---|---|---|

| Almandine | Fe3Al2(SiO4)3 | High hardness, relatively high density | Sandblasting, grinding, finishing |

| Pyrope | Mg3Al2(SiO4)3 | High hardness, medium density | Sandblasting, finishing |

| Spessartine | Ca3Al2(SiO4)3 | Medium hardness, low density | Industrial finishing |

| Grossular | Ca3Cr2(SiO4)3 | Medium hardness, low density | Industrial finishing |

Applications of Garnet Abrasive Mesh 60 in Various Industries

Garnet abrasive is a product with wide applications. It is utilized in many industries. The most important applications include:

- Sandblasting: Garnet mesh 60, due to its hardness and angular shape, is an ideal abrasive for sandblasting. This material cleans surfaces of metals, ceramics, and stones.

- Water Jet Cutting: This abrasive is very useful in water jet processes, which are conducted using high-pressure water. Garnet mesh 60 accurately cuts and cleans surfaces.

- Surface Finishing: Garnet mesh 60 helps create a uniform finish in surface finishing. This feature has made it popular in various industries.

- Oil and Gas Industries: This abrasive is used in cleaning and preparing surfaces in the oil and gas industries. Garnet mesh 60 aids in cleaning and preparing pipes, tanks, and equipment.

Price of Garnet Abrasive Mesh 60

The price of garnet mesh 60. Garnet is used in various industries such as sandblasting and surface finishing due to its suitable abrasive characteristics and high purity. The cost of purchasing one ton of garnet abrasive ranges from 200to200to300, depending on the supplier, purchase volume, and market conditions. Other factors such as shipping costs and currency fluctuations can also affect the final price. For accurate and up-to-date pricing, consulting local suppliers is recommended.

Garnet Abrasive Mesh 60 is beneficial due to its unique features across various industries.

| Industry | Application of Garnet Mesh 60 |

|---|---|

| Sandblasting | Cleaning and preparing metal, ceramic, and stone surfaces |

| Water Jet | Precision cutting and cleaning of surfaces |

| Surface Finishing | Creating a uniform and smooth finish |

| Oil and Gas | Cleaning and preparing pipes, tanks, and equipment |

Garnet mesh 60 has diverse applications across industries. This product serves as an efficient tool in these areas.

Advantages of Using Garnet Mesh 60 Abrasive

The use of garnet mesh 60 in various industries has many benefits, including economic efficiency, environmental compatibility, and high efficiency.

-

Cost-Effectiveness: Garnet is recognized as a cost-effective abrasive. It significantly reduces production costs. This abrasive can be reused multiple times in sandblasting processes, leading to substantial savings in material costs.

-

Environmental Compatibility: Compared to other abrasive materials, garnet mesh 60 is considered a green abrasive. This natural mineral is non-toxic and recyclable. Its use in sandblasting processes minimizes environmental pollution.

-

High Efficiency in Sandblasting: Garnet mesh 60, due to its high efficiency in sandblasting, enhances productivity. This abrasive possesses strong abrasive power and can prepare surfaces quickly and accurately.

In summary, the use of garnet mesh 60 offers significant advantages. These benefits are noteworthy across various industries and can be seen as a suitable and effective option in sandblasting processes.

Proper Storage and Maintenance Methods for Garnet

To maintain the quality of garnet, it is essential to follow proper maintenance and storage principles. Preventing moisture is crucial, as it can degrade garnet and reduce its efficiency. Therefore, it is advisable to avoid placing garnet in humid environments. For storage, use dry and cool warehouses.

Proper packaging is also vital for garnet. It protects garnet from contamination, impact, and other factors. Using plastic bags and appropriate barrels can be beneficial.

By adhering to proper storage conditions, we can maximize the useful life of garnet while maintaining its high quality.

In conclusion, there are important considerations for storing garnet. Moisture prevention and proper packaging are key factors that should be prioritized.

What Considerations Should Be Made When Buying and Using Garnet Mesh 60?

When purchasing garnet mesh 60, attention should be paid to its performance. Additionally, consider whether it is environmentally compatible. Cost savings are also important to keep in mind.

Remember that the maintenance and storage of garnet are also crucial.

What Unique Features Does Garnet Have?

Garnet is composed of a mixture of aluminum, silicon, and iron. This composition makes garnet very hard and resistant to abrasion.

Garnet has various types, including almandine and pyrope, which are used in industry.

In Which Industries is Garnet Mesh 60 Used?

Garnet abrasive is utilized in various industries. Among them are sandblasting, water jet cutting, and surface finishing.

Additionally, it has applications in the oil and gas industries.

What Advantages Justify the Use of Garnet Abrasive?

The use of garnet abrasive is justified by its economic benefits and environmental compatibility. This abrasive serves as a suitable alternative to other chemical materials.

How Can Garnet be Properly Stored and Maintained?

To properly store and maintain garnet, moisture must be prevented, and appropriate packaging should be utilized. Adhering to safety precautions is also essential. This ensures the quality and performance of garnet over time.