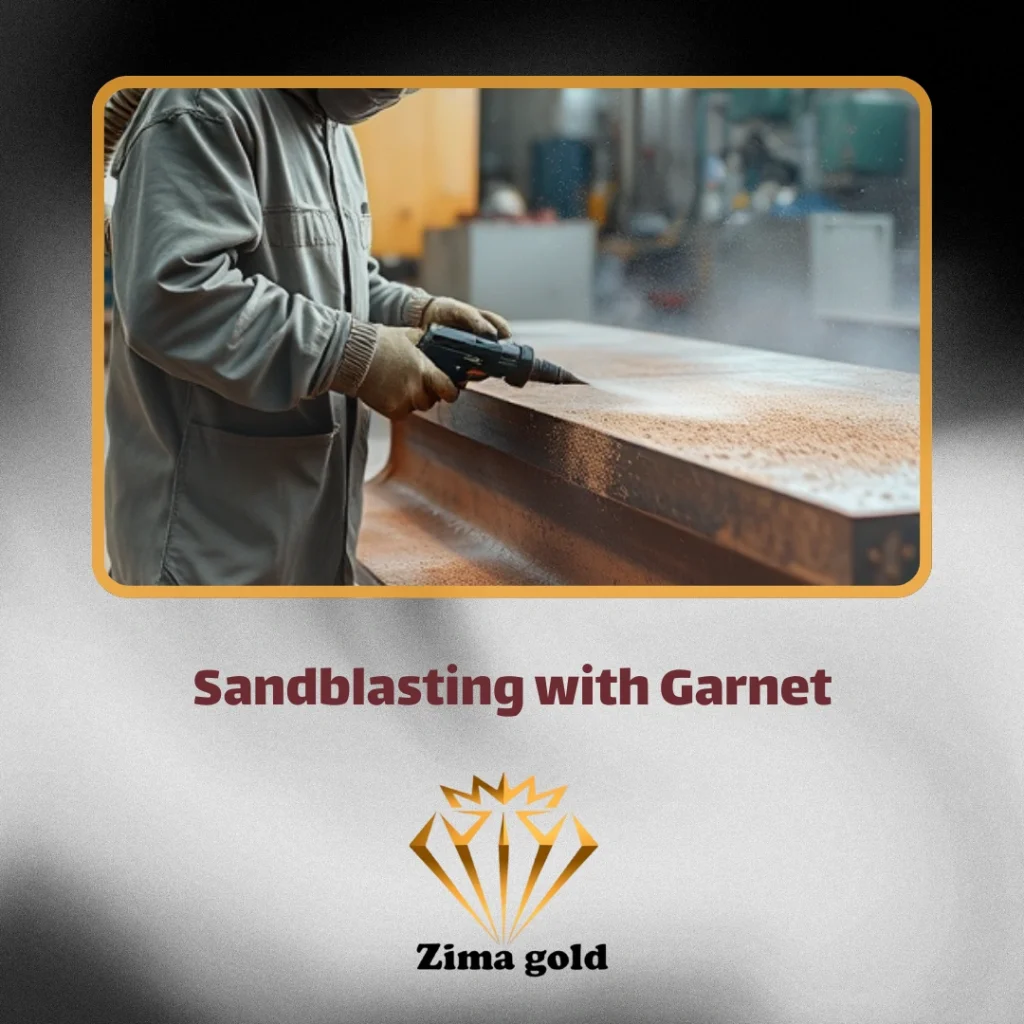

Sandblasting with Garnet

Sandblasting is an effective method for cleaning and shaping surfaces, where abrasive particles are propelled against the material. Garnet is recognized as one of the most popular abrasive materials in this process. This article examines the properties, advantages, disadvantages, and applications of sandblasting with garnet.

Mechanism of Sandblasting with Garnet

In the sandblasting process, particles are propelled at high pressure toward the material’s surface. These high-energy particles effectively remove contaminants and unwanted layers. The specialized equipment for this process includes a garnet tank, compressed air machine, and nozzles to control the flow of particles.

Garnet: The Ideal Abrasive

Garnet is a hard mineral with unique properties:

- Hardness: Ranges from 7 to 7.5 on the Mohs scale, making it an effective abrasive.

- Irregular Shape: Its structure allows it to effectively impact the surface properties of materials.

- Wear Resistance: Garnet is one of the abrasives with high wear properties.

Advantages of Sandblasting with Garnet

- High Cleaning Efficiency: Garnet easily removes contaminants and rust.

- Precision and Quality: This method typically delivers high precision and a smooth surface finish.

- Environmental Sustainability: Produces less dust compared to other abrasive materials.

- Minimal Heat Generation: This process does not generate significant heat that could damage surfaces.

- High Speed: The hardness of garnet accelerates the cleaning process.

Disadvantages of Sandblasting with Garnet

- High Cost: Garnet generally has a higher price than other abrasive materials.

- Equipment Wear: Continuous use may damage equipment.

- Need for Specialized Equipment: Effective use requires specific tools and machines.

- Sensitivity to Environmental Conditions: Humidity and temperature can influence performance.

Applications of Sandblasting with Garnet

- Automotive Industry: For cleaning and preparing surfaces.

- Construction: Removal of paint and rust from structures.

- Filter Production: Used in water and air filters.

- Artistic Work: Creating textures and intricate designs.

- Pharmaceutical and Healthcare: Cleaning medical devices and tools.

Conclusion

Sandblasting is an effective technology in the surface cleaning and shaping industry. Despite higher initial costs, it offers significant advantages such as cleanliness, precision, and environmental safety. Choosing the appropriate garnet and being aware of environmental conditions before utilizing this method are key factors for achieving superior results.

Buying Garnet for Sandblasting

Purchasing garnet for sandblasting from Zimagold is one of the best options to enhance the quality and efficiency of your industrial projects. Zimagold, as a reputable supplier, offers high-quality garnet known for its excellent abrasive properties and environmental compatibility. This mineral serves as an efficient abrasive in sandblasting processes, aiding in the cleaning of metal, concrete, and other materials while extending the lifespan of your equipment. By buying garnet from Zimagold, you can easily access the best raw materials and ensure that your projects are completed with maximum quality and efficiency.