Garnet Waterjet

Introduction

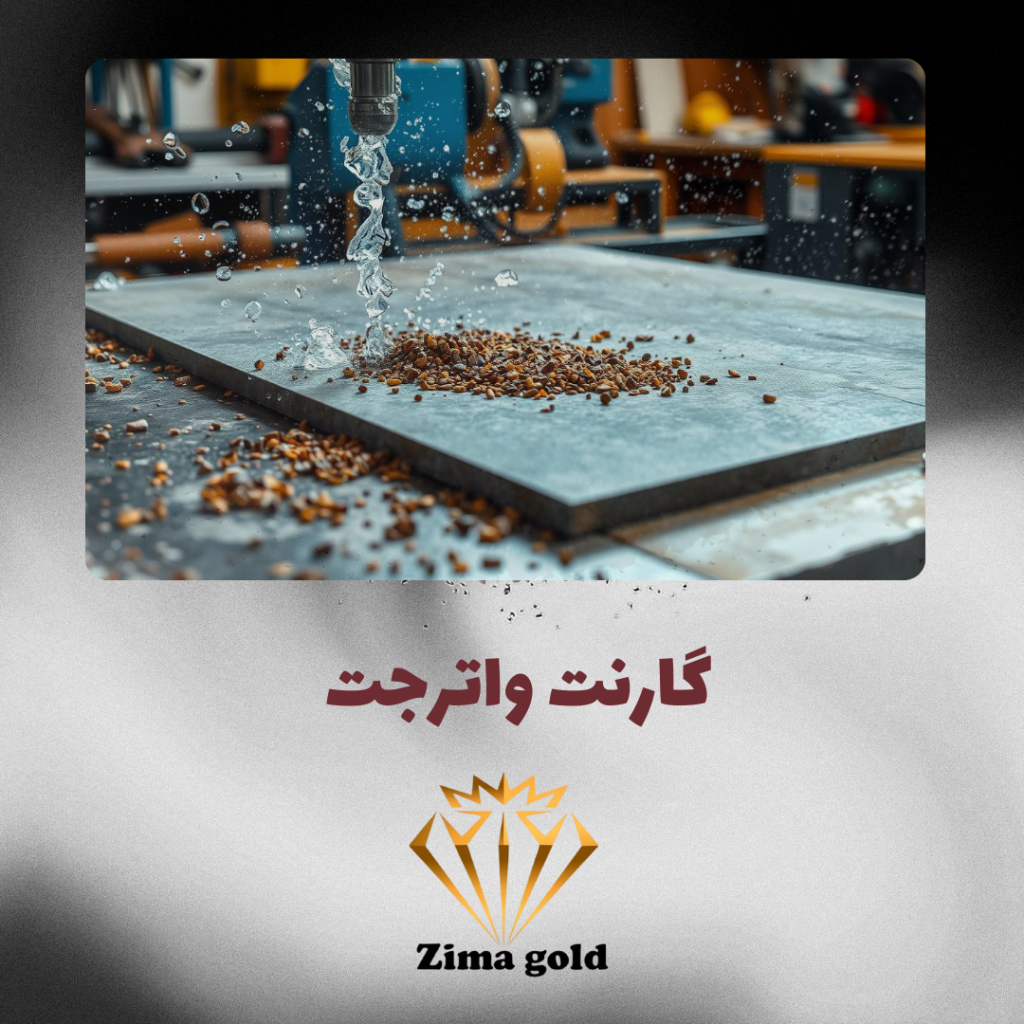

Garnet waterjet is a cutting-edge technology that utilizes high-pressure water and abrasive garnet particles to cut and clean various surfaces such as metals, stone, and concrete. This method is widely recognized as a suitable alternative to other cutting and cleaning techniques across various industries.

Key Points

– Advanced water pressure cleaning technology

– Wide applications across various industries

– Cutting and cleaning of metallic, stone, and concrete surfaces

– Suitable substitute for other cutting and cleaning methods

– Use of garnet abrasive particles for enhanced efficiency

How Garnet Waterjet Works

In a garnet waterjet system, a powerful pump directs high-pressure water to a nozzle, which sprays garnet abrasive particles at high speed onto the target surface. This process makes garnet waterjet effective for cutting and cleaning a variety of materials in industries such as construction, mining, metalworking, and stone processing.

Diverse Applications in Various Industries

Garnet waterjet can cut and clean a wide range of materials, including steel, alloys, stone, concrete, and even composites. Its applications span across several sectors:

– Construction Industry: Cutting and cleaning concrete and stone surfaces.

– Mining Industry: Cleaning and cutting mineral stones.

– Metalworking Industries: Cutting and cleaning metal parts.

– Stone Industry: Cutting and finishing construction stones.

– Composite Industries:Cutting and cleaning composite products.

This technology is extensively used across these industries, recognized as an effective and efficient solution.

Advantages of Using Garnet Waterjet

Garnet waterjet offers numerous benefits, making it a favorable alternative to older methods. Key advantages include:

– No heat generation during processing, preventing damage to the workpiece.

– Precise control over cutting depth, allowing for detailed processing and penetration into multiple layers.

– No environmental waste or pollution due to the absence of chemicals.

– Lower costs compared to traditional cutting and cleaning methods.

– High flexibility for various applications and the ability to process different surfaces.

These features showcase the significant advantages of garnet waterjet over other methods, establishing it as a preferable choice.

Types of Garnet Waterjet Systems

Garnet waterjet systems are categorized into two types: portable and fixed. Each type has specific features tailored for different applications.

Portable Garnet Waterjet Systems

Portable systems are suitable for specific and fieldwork tasks. They are lightweight and easily transportable, making them ideal for small-scale cleaning and cutting jobs.

Fixed Garnet Waterjet Systems

Fixed systems are used for industrial applications. These systems are set up in permanent production lines and operate continuously, providing high power and capacity for larger-scale tasks.

Choosing the Right Garnet Waterjet System

To select the appropriate garnet waterjet system, various factors must be considered, including application type, dimensions and sizes of parts, thickness and material of surfaces, production volume needed, and space constraints. Careful evaluation of these factors and consulting with experts can assist in choosing the suitable garnet waterjet system.

Application type is critical. Do you require cleaning soft and sensitive surfaces or processing tough and thick parts? This question determines which features of the garnet waterjet system will be most suitable for your needs.

The size and dimensions of the parts being processed are also important. Portable systems are preferable for smaller projects, while fixed industrial systems are better for handling larger parts and higher volumes.

Finally, site space limitations for installing the garnet waterjet system should be considered, aiding in the selection of the appropriate system.

By considering these factors and seeking expert advice, one can find a garnet waterjet system that meets the specific needs of any business.

Summary

Garnet waterjet is an advanced technology that effectively cuts and cleans various surfaces using high-pressure water and garnet abrasive particles. This technology offers numerous advantages, such as no heat generation and precise cutting control.

Additionally, it operates without causing environmental pollution and is cost-effective, making it an excellent replacement for traditional methods.

Garnet waterjet systems are available in both portable and fixed industrial configurations and are suitable for various industries. By evaluating several factors, you can choose a garnet waterjet system that fits your specific requirements.

Overall, the summary of garnet waterjet illustrates that this advanced technology efficiently performs the cutting and cleaning of various surfaces, making it an ideal alternative to traditional methods.

FAQ

What factors influence the selection of an appropriate garnet waterjet system?

To choose the right garnet waterjet system, key factors to consider include application type, dimensions and sizes of parts, thickness and material of surfaces, production volume required, and space limitations. Analyzing these factors and consulting experts can help in making the right choice.

What types of garnet waterjet systems exist?

Garnet waterjet systems are divided into portable and fixed types. Portable systems are suitable for field applications and are easily movable, while fixed systems are designed for industrial and production use, installed permanently in manufacturing lines.

What are the advantages of using garnet waterjet?

Garnet waterjet has many advantages, including high power and the ability to cut and clean various surfaces. This technology operates without generating heat, provides precise control over cutting depth, produces no waste or environmental pollution, is cost-effective, and offers high flexibility.

What are the applications of garnet waterjet in various industries?

Garnet waterjet is used in various industries, including construction, mining, metalworking, and stone processing. It is effective for cutting and cleaning materials such as steel, alloys, stone, and concrete, and is also suitable for composites.

How does garnet waterjet work?

In garnet waterjet, a powerful pump directs high-pressure water to a nozzle, which sprays garnet abrasive particles at high speed onto the target surface, enabling cutting and cleaning. This technology is applicable for cleaning and cutting tough and resilient materials across different industries.